Defining a new model for a relatively new company in the marketplace is always challenging. With Borg, we made our second model a success by combining innovation and more of the same.

For our third model, KIM, we asked our dealers and distributors, and they asked for either a more expensive model or a lower-priced model, but there was no clear trend.

So, we did what we are good at – we made it our way again – a mixture of innovation and more of the same. KIM had to be a speaker that we would use ourselves, something fun. We designed another speaker for us.

Here’s a list of the Kim reviews.

TECHNOLOGIES

- Colours

- Kim Cabinet

- Kim Crossover and Impedance

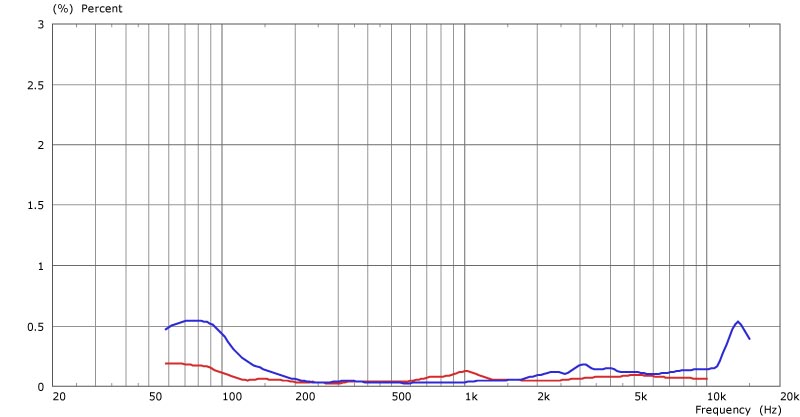

- Kim Distortion

- Kim Mid/Bass Driver

- Kim AMT HF Unit

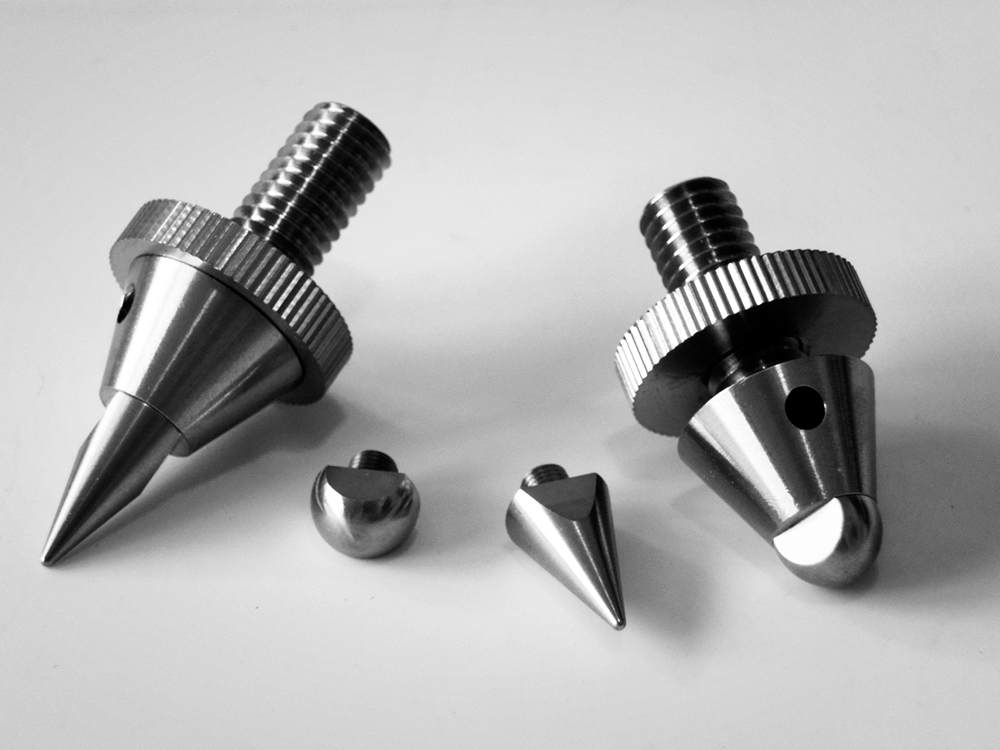

- Spikes / Domes

KIM Standard Finishes

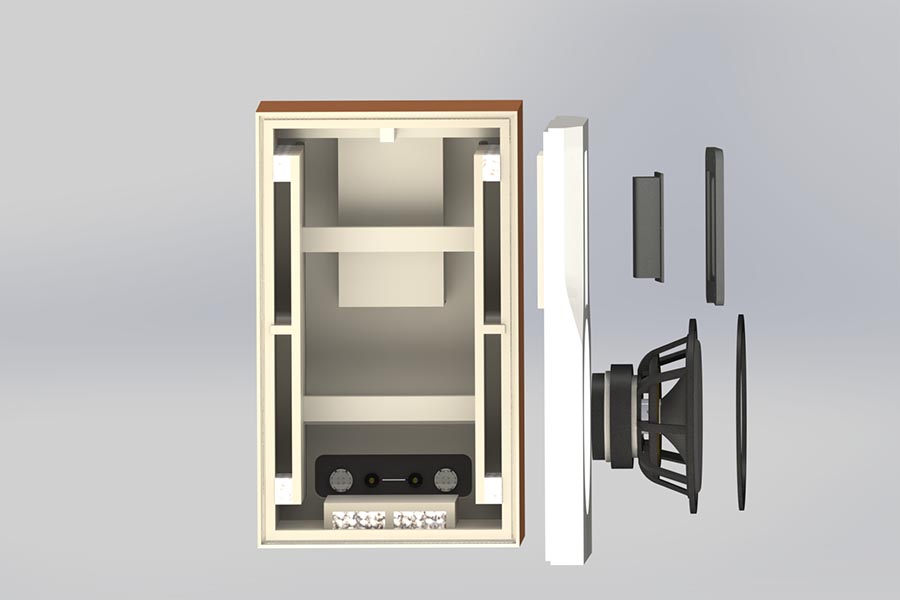

FinkTeam cabinets or enclosures are always works of art inside and out. The construction centres around two critical tasks: to hold the drive units still in space and to radiate as little energy as possible.

We have talked before about the signal to noise ratio of a loudspeaker cabinet, and it is still one of those fundamentals in our thinking. It’s pointless to design and manufacture state of the art drive units and engineer crossovers with perfect knits if the cabinet is singing along with the tune.

We think of loudspeaker system design as something where the integration of the parts is a positive-sum game.

The sculptured front baffle of KIM reducing in width from 300mm to 205mm around the AMT is to aid high-frequency directivity and minimise diffraction. Multi-layers of MDF panels glued together with a new unique damping adhesive form the front baffle, which is then precision CNC routed. The sides and rear of the enclosure utilise a similar technique, but the panels are only a single sandwich.

Bracing is one-dimensional to avoid the unnecessary spread of panel resonances common in modern loudspeaker designs. Designing for the lowest radiated energy is almost impossible without the benefits of laser interferometry and FEA.

Strunk absorbers are used inside the enclosure to remove standing waves. These Helmholtz resonators in anti-phase to the standing waves cancelling them without the deleterious use of masses of absorbent material.

For years the argument has raged among loudspeaker designers between those that ’stuff‘ their boxes full of polyester fibre or sheep’s wool or other ‚magic‘ absorbent and those who prefer a relatively empty box. Like all design elements, there are arguments favouring both, but to simplify it here * masses of stuff tends to ’slow‘ the speaker’s sound but possibly give it a more hi-fi sounding but less fun or involving performance.

xxx

xxx

xxx

xxx

xxx

xxx

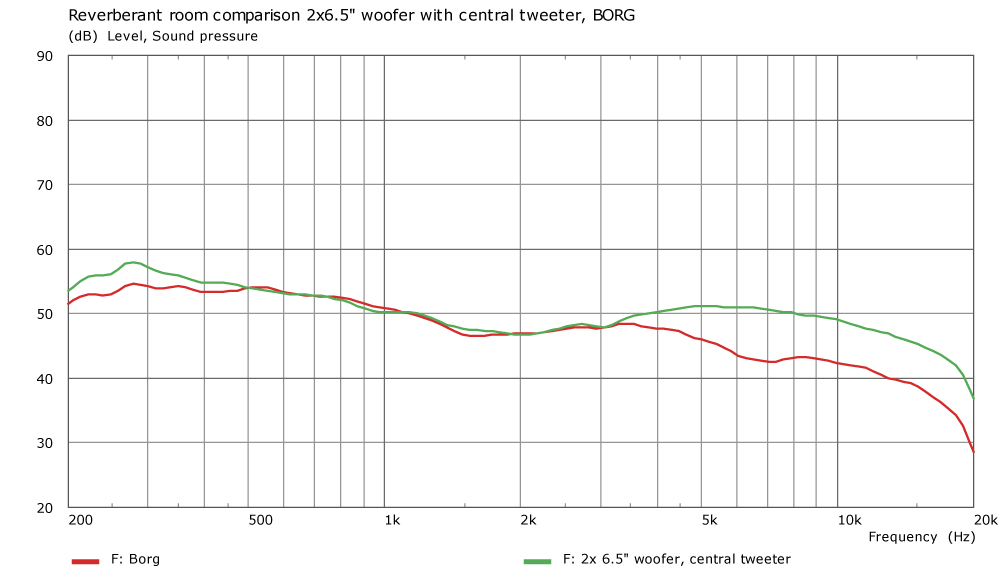

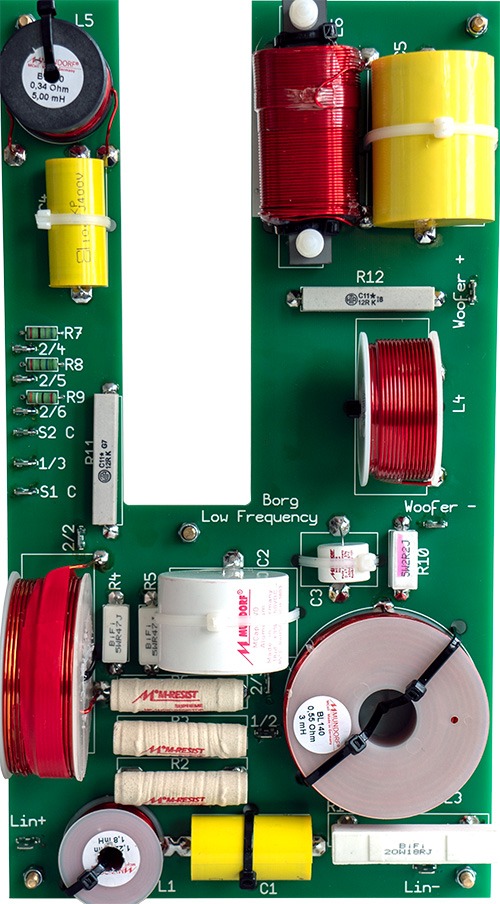

Borg LF Crossover

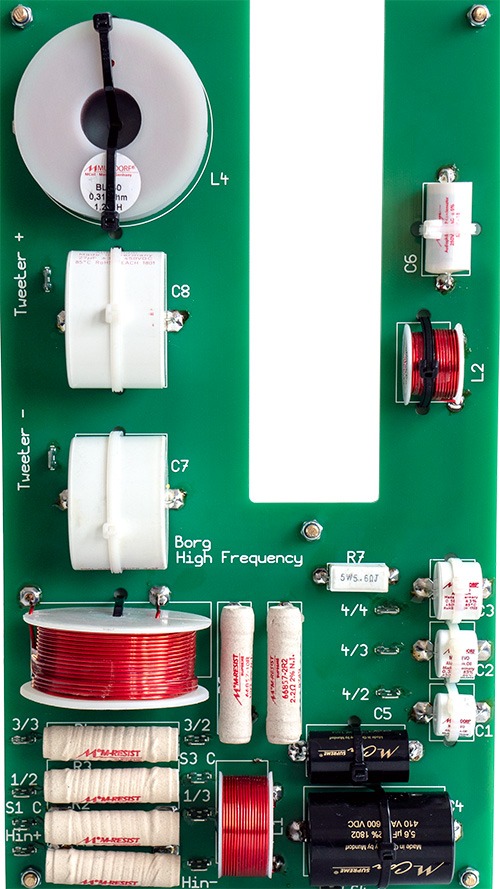

Borg HF Crossover

xxx

xxx

xxx

The trend since the 80s has been for slim loudspeakers, which has necessitated the use of smaller mid/bass drive units. The classic two-way loudspeaker went from being an eight-inch with a 19mm tweeter to a six and a half to a five or even four-inch mid/bass, and at the same time, tweeters generally moved to 25 or 29mm.

Materials technology and better adhesives have allowed massive changes to power handling, maximum excursion, and reliability, encouraging smaller drive-unit systems.

With KIM, we wanted to design a speaker we would use ourselves, forcing us in the direction of an 8inch mid-bass driver.

Similarly, as we said with the 10.25inch driver unit of Borg, a great 8inch will not beat a great 10.25 incher, but it can deliver a full range performance with only a small compromise on maximum SPL.

Unlike our previous bass and mid-bass drivers, we needed a sizeable half-roll surround to allow the excursion due to the smaller pulp paper cone. The softer rubber half-roll surround also terminates the cone correctly to eliminate colouration caused by energy returned to the cone from the cone surround.

From our learnings from Borg development, the mid/bass has an oversized magnet. This ensures a Q that is too high and which alone would reduce the low-frequency performance. Combined with the higher than convention resistance of the primary inductor feeding the driver, the Q is corrected, enabling the system to deliver clean, accurate in-room bass to 32Hz—a clever solution to using an air-core inductor for the lowest distortion.

The tweeter is an Air Motion Transformer (AMT) operating according to the principles established by its inventor Oskar Heil. Developed by Mundorf together with FinkTeam and manufactured specifically for FinkTeam by Mundorf, the AMT has a strong, 25μm-thick pleated Kapton diaphragm with 50μm aluminium strips. This material has excellent internal damping, resulting in particularly low distortion. We developed a unique etching process to produce it, and the diaphragm configuration optimised through many tests.

The choice of 110mm AMT delivers a wide dispersion horizontally – giving good stereo across a wide listening area. The directivity vertically is deliberately controlled to reduce floor and ceiling reflections that may harm the imaging and reduce the apparent image height.

xxx

xxx

xxx